- Work with us

- Repairs

- Contact

- +34 972 640 620

- Home

- Loading bay equipment

- Freezing loading docks

- Isoperfect loading and unloading system

Angel Mir products

Isoperfect system

In the classic system of loading and unloading in conventional bays and during all the sequential process, the merchandise is exposed to external agents such as changes of temperature, rainfalls, pollutant gases coming from the combustion of the vehicle itself, etc.

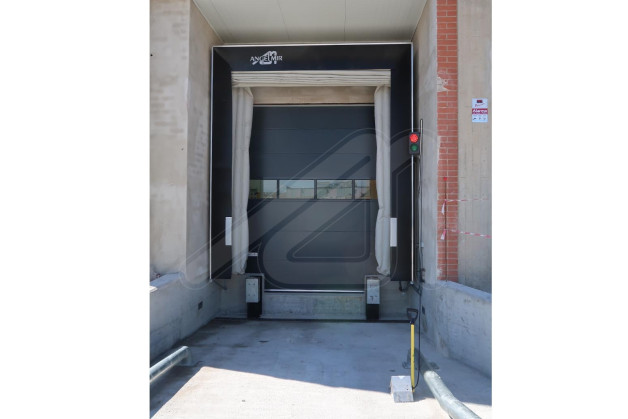

Isoperfect is the ideal dock seal for freezing and cold industries beacuse it keeps a stable temperature anytime by opening the truck doors inside the dock, avoiding the goods being affected by adverse agents like insects, smoke or dust. It is the appropriate system to fulfill IFS and BRC Food Safety Certifications.

Isoperfect is a fast and functional system thanks to a single control panel for all the loading bay equipment. Furthermore, the design of the whole set brings a huge energy saving and minimizes the risk of accidents, as well in potential thefts.

For a perfect dock seal in loading bay:

ISOPERFECT PLUS: in order to improve and achieve an absolutely hygienic exchange of goods and at a stable temperature in the loading docks, ISOPERFECT PLUS includes the new sealing cushion AH 4BAGS at below. This inflatable dock shelter seals completely all around the truck with high insulation. It also represents a significant reduction in energy costs and greatly saving energy costs.

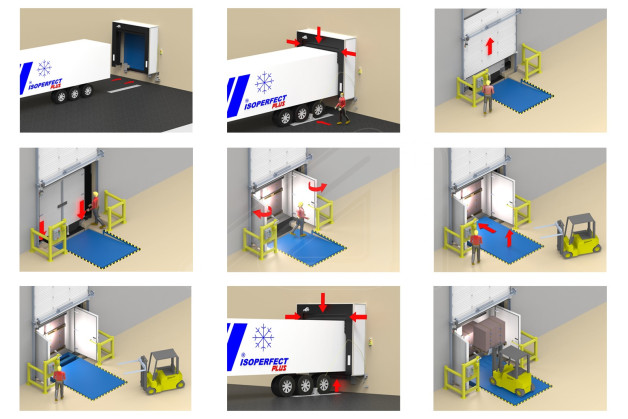

Operation:

- Approaching: approaching of the vehicle in the loading dock with the help of the positioning system through guides. The truck doors remain closed.

- Sealing: the truck moves back up and touches the bumpers, and stops. Then it advances a few centimetres forward to release the bumpers, and stops. At this moment, the truck is positioned in the loading bay. And then the dock shelter inflation takes place (AH 36-37 ISO or ECO).

- Opening: it takes place the opening of the loading dock door.

- Partial lip extension, dropping of the ramp and the bumpers: the lip is extended and the ramp descends to almost touching the truck body. So the free space between the truck and the ramp is bridged. Then the movable bumpers are lowered.

- Opening truck doors: mounting of the truck doors through the locking device, if this feature has been requested. Switching on the Versalight spotlight to allow enough light to work inside the vehicle or container.

- Ramp levelling: the operator levels the ramp across the vehicle through the position of the retractable lip in the Telesco ramp model, easily bridging the gap with the truck, positioned with millimetre precision.

- Loading / unloading: to perform the loading and unloading operations in a safe and efficient way. Without heat losses and maximum safety of the product.

- Gathering up the lip and lowering the ramp: gather up the lip up to some centimetres further from the end of the truck body and lower the ramp down to the low level to be able to close the truck doors. The usable space between the lip and the truck must be closed with the lip extension to avoid potential accidents.

- Door closing: the goods loaded on the truck are not exposed to the adverse weather conditions.

- Lifting up the bumpers and removing completely the lip: bumpers in reception position by steeping on the freeing pedal. Gather up completely the lip of the ramp

- Closing the door of the loading dock: thanks to this process, the warehouse remains protected against the tough weather conditions and the external pollution.

- Closing the dock shelter: the shelter returns to its resting position and the truck is now free and can move away.

Request budget for

CATALOGUES

- es-Puntos-de-carga-AM

- en-Loading-bay-equipment-AM

- fr-Quais de chargement-AM

- es-Sistema-isoperfect-AM

- en-Isoperfect-system-AM

en

en  es

es ca

ca fr

fr

Àngel Mir

Àngel Mir